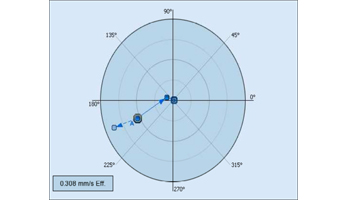

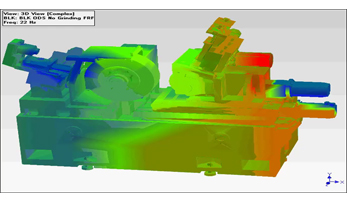

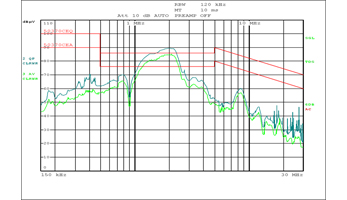

Vibration analysis is a process of looking for anomalies and monitoring change from the established vibration signature of a system. The vibration of any object in motion is characterized by variations of amplitude, intensity, and frequency. These can correlate to physical phenomena, making it possible to use vibration data to gain insights into the health of equipment.

Vibration analysis can be used to

Services AMTTF can provide

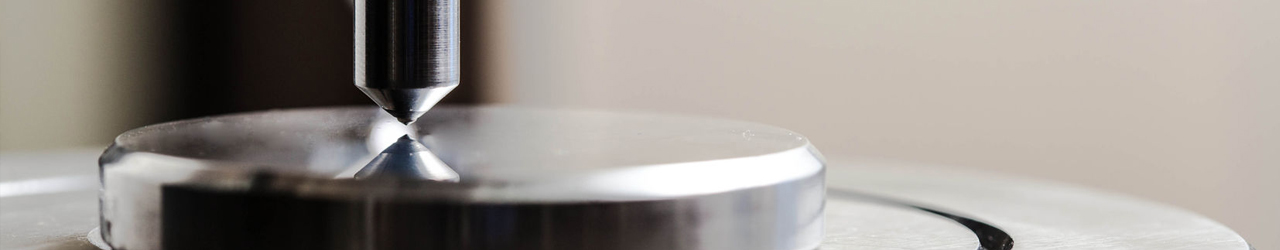

AMTTF is equipped with the latest state of art equipment to cater the testing services of any CNC/Conventional Machines.

Services AMTTF can provide

AMTTF can offer third party inspection services of new/used machinery.

Services AMTTF can provide

AMTTF had carried out several third party inspection for the procurement of machinery by government sectors as well as private companies.

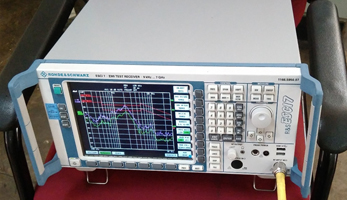

AMTTF is equipped with the latest state of art equipment to carry out the prototype testing/ type testing of CNC/Conventional Machines, subsystems and other engineering products.

AMTTF can carry out the testing of the products as per National/ International Standards and certify the products for its functionality/Performance and reliability.

The Equipment Performance is evaluated with reference to the relevant parts of BS EN/ IEC/ CISPR standards, and the evaluation is done for conducted Emission and Radiated Emission and Immunity.

Services AMTTF can provide

AMTTF is equipped with the latest state of art equipment and Trained Engineers to carry out the calibration services of CNC Machines.

Services AMTTF can provide

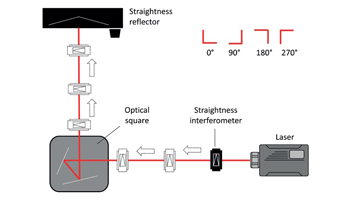

AMTTF is equipped with the Renishaw Laser kit with full set of optics including Straightness, Squareness and Flatness optics.

Services AMTTF can provide

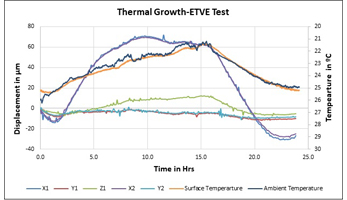

AMTTF carry out detailed Thermal Analysis of Machines under Normal / Controlled Environmental Conditions.

Services AMTTF can provide

Residual Stress Analysis & Retained Austenite Measurement helps to study the manufacturing processes to improve the fatique life of components used in Automobiles/ machine tools and other industries.

Services AMTTF can provide

AMTTF is equipped with a metrology lab necessary equipment for inspection and calibration of dimensional measuring instruments.

Services AMTTF can provide

© 2024 AMTTF. All Rights Reserved